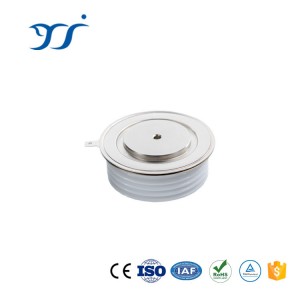

Sarrafa Mataki na Thyristor

Sarrafa lokaci Thyristor (Nau'in Alloying)

Bayani:

Thyristor, wanda kuma aka sani da Silicon Control Rectifier (SCR), na'ura ce mai ƙarfi mai ƙarfi wacce ta ƙunshi tsarin PN guda uku.Dangane da aikin, thyristor ba wai kawai yana da karkatar da kai tsaye ba, har ma yana da ikon sarrafawa mafi mahimmanci fiye da nau'in gyaran gyare-gyaren silicon, wanda kawai jihohi biyu na gudanarwa da kashe-jihar, don sarrafa babban iko tare da ƙaramin ƙarfi, haɓaka wutar lantarki har zuwa ɗaruruwa ko sau dubbai.Halin yana da sauri sosai, yana kunnawa da kashewa a cikin ƙananan daƙiƙa.Ayyukan da ba a haɗa su ba, babu tartsatsi, babu hayaniya, yayin da inganci da ƙananan farashi.Sabili da haka, musamman a cikin babban tsarin samar da wutar lantarki, an yi amfani da thyristor sosai a cikin da'irar gyarawa, madaidaicin kewayawa, canjin fitarwa mara lamba da sauran da'irori.

The thyristor masana'antu misali da kuma sarrafa fasahar RUNAU Electronics aka gabatar daga Amurka tun 1980s, a matsayin majagaba na masana'antu thyristor a kasar Sin, da fasaha tawagar RUNAU sun sami sabon-baki ilmi da isasshen masana'antu kwarewa fiye da shekaru 30.A kan tushen tsarin masana'antu na gargajiya, ƙwararrun masu fasaha na RUNAU Electronics sun haɓaka fasahar fasahar kere-kere a cikin kera thyristor tare da fa'idodin samfuran Turai, inganci da aiki suna haɓaka sosai, ƙarin manyan nasarorin da aka samu a aikace-aikacen lantarki na lantarki. filayen, kuma an ƙirƙiri ƙarin ƙima don abokan haɗin gwiwa.

Gabatarwa:

1. Chip

Thyristor guntu da RUNAU Electronics ya ƙera ana amfani da fasahar haɗaɗɗen haɗakarwa.An siyar da siliki da wafer molybdenum don haɗawa ta hanyar aluminium mai tsafta (99.999%) a ƙarƙashin babban vacuum da yanayin zafin jiki.Gudanar da halayen sintering shine babban abin da zai shafi ingancin thyristor.The sani-yadda na RUNAU Electronics ban da sarrafa gami junction zurfin, surface flatness, gami rami da cikakken yaduwa fasaha, cibiyar ƙofar, zobe da'irar juna da aka yi amfani da su ba da damar da abin dogara da kuma high m conduction aiki na thyristor, domin tabbatar da babban ingancin aiki.

2. Encapsulation

Ta hanyar tsananin sarrafa faɗuwa da daidaiton molybdenum wafer da fakitin waje, guntu da wafer molybdenum za a haɗa su tare da fakitin waje tam kuma gaba ɗaya.Irin wannan zai inganta juriya na hawan halin yanzu da babban gajeriyar da'irar halin yanzu.Kuma an yi amfani da ma'aunin fasahar evaporation na lantarki don ƙirƙirar fim mai kauri na aluminum akan saman silicon wafer, kuma ruthenium Layer plated akan molybdenum surface zai haɓaka juriya na zafin thermal sosai, lokacin rayuwar aikin thyristor zai ƙaru sosai.

Ƙayyadaddun fasaha

- Thyristor mai sarrafa lokaci tare da guntu nau'in alloy wanda RUNAU Electronics ya ƙera, kewayon ITAVdaga 300A zuwa 6000A da VDRM/VRRMdaga 800 zuwa 4400 V.

- IGT, VGTkuma IHsune ƙimar gwajin a 25 ℃, sai dai in an faɗi in ba haka ba, duk sauran sigogi sune ƙimar gwajin ƙarƙashin Tjm;

- I2t=I2F SM ×tw/2, tw= Sinusoidal rabin kalaman nisa na yanzu.A 50Hz, I2t=0.005I2FSM (A2S);

- a 60Hz: IFSM(8.3ms) = IFSM(10ms)×1.066,Tj=Tj;I2t(8.3ms)=I2t (10ms) × 0.943,Tj=Tjm

Siga:

| TYPE | IT (AV) A | TC ℃ | VDRM/VRRM V | ITSM@TVJIM &10ms A | I2t A2s | VTM @IT&TJ=25℃ V/A | Tjm ℃ | Rjc ℃/W | Rcs ℃/W | F KN | m Kg | CODE | |

| Wutar lantarki Har zuwa 1800V | |||||||||||||

| 320 | 70 | 1200-1800 | 3840 | 7.4x104 | 1.60 | 600 | 125 | 0.08 | 0.02 | 4 | 0.060 | T1A | |

| 400 | 70 | 1200-1800 | 4800 | 1.1x105 | 1.60 | 1200 | 125 | 0.045 | 0.01 | 13 | 0.200 | T3C | |

| 600 | 65 | 1200-1800 | 7200 | 2.6x105 | 1.65 | 1500 | 125 | 0.04 | 0.008 | 15 | 0.260 | T5C | |

| 800 | 70 | 1200-1800 | 9600 | 4.6x105 | 1.60 | 1500 | 125 | 0.039 | 0.008 | 15 | 0.260 | T5C | |

| 1000 | 70 | 1200-1800 | 12000 | 7.2x105 | 1.45 | 1500 | 125 | 0.03 | 0.006 | 20 | 0.330 | T7C | |

| 1200 | 70 | 1200-1800 | 14400 | 10.0x105 | 1.60 | 3000 | 125 | 0.022 | 0.005 | 25 | 0.460 | T8C | |

| 1500 | 70 | 1200-1800 | 18000 | 1.6x106 | 1.55 | 3000 | 125 | 0.018 | 0.005 | 27 | 0.593 | T9C | |

| 1800 | 70 | 1200-1800 | 21600 | 2.3x106 | 1.50 | 3000 | 125 | 0.015 | 0.0045 | 30 | 0.720 | T10C | |

| 2500 | 70 | 1200-1800 | 30000 | 4.5x106 | 1.45 | 3000 | 125 | 0.0125 | 0.004 | 33 | 0.850 | T11C | |

| 3000 | 70 | 1200-1800 | 36000 | 6.5x106 | 1.40 | 3000 | 125 | 0.01 | 0.003 | 35 | 1.100 | T13C | |

| 4000 | 65 | 1200-1800 | 48000 | 11.5x106 | 1.35 | 3000 | 125 | 0.008 | 0.002 | 60 | 1.400 | T15C | |

| 6000 | 65 | 1200-1800 | 72000 | 26.0x106 | 1.30 | 5000 | 125 | 0.006 | 0.0015 | 80 | 1.900 | T16C | |

| Wutar lantarki Har zuwa 2400V | |||||||||||||

| 500 | 70 | 2000-2400 | 7000 | 2.5x105 | 1.80 | 1500 | 125 | 0.039 | 0.008 | 15 | 0.260 | T5C | |

| 800 | 70 | 2000-2400 | 11200 | 6.3x105 | 1.80 | 2400 | 125 | 0.03 | 0.006 | 20 | 0.330 | T7C | |

| 1000 | 70 | 2000-2400 | 14000 | 7.2x105 | 1.80 | 3000 | 125 | 0.022 | 0.005 | 25 | 0.460 | T8C | |

| 1200 | 70 | 2000-2400 | 14400 | 10.0x105 | 1.80 | 3000 | 125 | 0.02 | 0.005 | 27 | 0.500 | T8C | |

| 1500 | 70 | 2000-2400 | 18000 | 1.6x106 | 1.70 | 3000 | 125 | 0.015 | 0.0045 | 30 | 0.720 | T10C | |

| 2100 | 70 | 2000-2400 | 24000 | 2.9x106 | 1.60 | 3000 | 125 | 0.0125 | 0.004 | 33 | 0.850 | T11C | |

| 3000 | 65 | 2000-2400 | 36000 | 6.5x106 | 1.45 | 3000 | 125 | 0.01 | 0.003 | 35 | 1.100 | T13C | |

| 5700 | 65 | 2000-2400 | 68400 | 23.0x106 | 1.30 | 5000 | 125 | 0.006 | 0.0015 | 80 | 1.900 | T16C | |

| Wutar lantarki Har zuwa 3200V | |||||||||||||

| 500 | 70 | 2600-3200 | 7000 | 2.5x105 | 2.15 | 1500 | 125 | 0.039 | 0.008 | 15 | 0.260 | T5C | |

| 1000 | 70 | 2600-3200 | 12000 | 7.2x105 | 2.10 | 2500 | 125 | 0.022 | 0.005 | 25 | 0.460 | T8C | |

| 1200 | 70 | 2600-3200 | 14400 | 1.0x106 | 2.00 | 3000 | 125 | 0.018 | 0.005 | 27 | 0.593 | T9C | |

| 1700 | 70 | 2600-3200 | 20400 | 2.1x106 | 1.95 | 3000 | 125 | 0.015 | 0.0045 | 30 | 0.720 | T10C | |

| 2000 | 70 | 2600-3200 | 24000 | 2.9x106 | 1.85 | 3000 | 125 | 0.0125 | 0.004 | 33 | 0.850 | T11C | |

| 2500 | 70 | 2600-3200 | 25200 | 3.2x106 | 1.75 | 3000 | 125 | 0.011 | 0.003 | 35 | 1.500 | T13D | |

| 3700 | 65 | 2600-3200 | 44400 | 9.9x106 | 1.65 | 3000 | 125 | 0.008 | 0.002 | 60 | 1.990 | T15D | |

| 4500 | 65 | 2600-3200 | 54000 | 1.5x107 | 1.65 | 5000 | 125 | 0.006 | 0.0015 | 80 | 1.900 | T16C | |

| Wutar lantarki Har zuwa 4200V | |||||||||||||

| 480 | 70 | 3600-4200 | 5760 | 1.7x105 | 2.40 | 1200 | 125 | 0.039 | 0.008 | 15 | 0.260 | T5C | |

| 1000 | 70 | 3600-4200 | 12000 | 7.2x105 | 2.45 | 2500 | 125 | 0.022 | 0.005 | 25 | 0.460 | T8C | |

| 1200 | 70 | 3600-4200 | 14400 | 1.0x106 | 2.40 | 3000 | 125 | 0.016 | 0.005 | 28 | 0.650 | T9C | |

| 1500 | 70 | 3600-4200 | 18000 | 1.6x106 | 2.50 | 3000 | 125 | 0.015 | 0.0045 | 30 | 0.720 | T10C | |

| 1900 | 70 | 3600-4200 | 22800 | 2.6x106 | 2.30 | 3000 | 125 | 0.0125 | 0.004 | 33 | 0.850 | T11C | |

| 2100 | 65 | 3600-4200 | 24000 | 2.9x106 | 2.20 | 3000 | 125 | 0.011 | 0.003 | 35 | 1.500 | T13D | |

| 3000 | 70 | 3600-4200 | 36000 | 6.5x106 | 1.70 | 3000 | 125 | 0.008 | 0.002 | 60 | 1.990 | T15D | |

| 3800 | 70 | 3600-4200 | 45600 | 1.0x107 | 1.90 | 5000 | 125 | 0.006 | 0.0015 | 80 | 1.900 | T16C | |